Recycled beverage carton walls for Australian buildings

An SIG-backed beverage carton recycling project has won a A$1.74 million grant from the Federal and New South Wales (NSW) Government towards setting up a A$5 million facility that will turn post-consumer beverage cartons and paper cups into high performance building material.

An SIG-backed beverage carton recycling project has won a A$1.74 million grant from the Federal and New South Wales (NSW) Government towards setting up a A$5 million facility that will turn post-consumer beverage cartons and paper cups into high performance building material. The project is funded by the Australian Government’s Recycling Modernisation Fund and the NSW Government’s Waste Less, Recycle More initiative.

The Australian and NSW Governments and the companies behind the project expect the facility will create confidence in a new market for recycled construction materials, similar to roads made from recycled glass, and enable more packaging to become 100 per cent recyclable, in line with Australian national packaging targets.

The project is the first collaboration between SIG and Tetra Pak in Australia under the umbrella of the Global Recycling Alliance for Beverage Cartons and the Environment (GRACE) and is a joint initiative with saveBOARD and its supporters Freightways and Closed Loop.

The Australian Packaging Covenant Organisation (APCO) says this is a fantastic step forward for beverage cartons and for the brands and consumers that use this important type of packaging.

saveBOARD co-founder and Chief Executive Officer Paul Charteris says making high-performance low-carbon building materials using 100 % recycled materials from everyday waste is a game-changer that will transform the construction industry in Australia.

The first Australian saveBOARD plant will reprocess liquid paperboard beverage containers, including both aluminium-lined aseptic packages and non-aluminium-lined containers collected through the container deposit scheme and coffee cups collected through the ‘Simply Cups’ recycling program. It will also source material from document recycling company Shred-X.

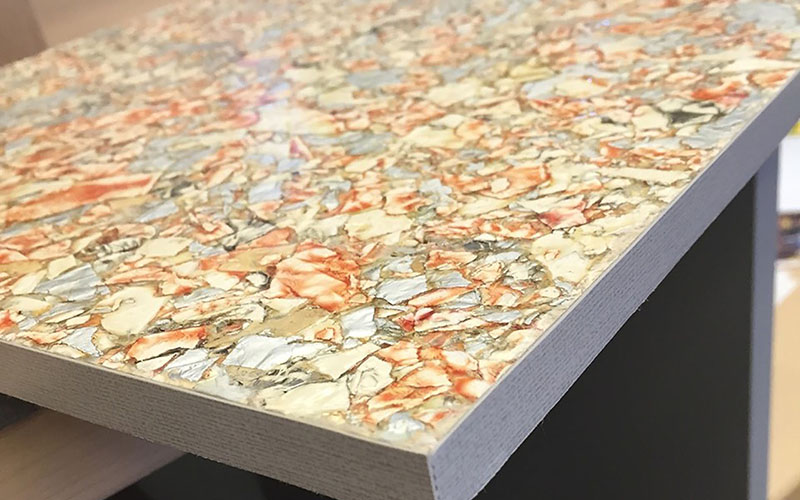

Together with supplementary material from industrial processes, these items will be used to manufacture high-performance low-carbon building products to substitute plaster board, particle board, and oriented strand board (OSB) that can be used for interior and exterior applications.

The saveBOARD process uses heat and compression to bond materials, eliminating the need for glues or other chemical additives, to produce a clean product with zero volatile organic compounds (VOCs), suitable for use in homes and commercial buildings.